Wet Granulation Process

Introduction

Wet granulation is a critical process in the pharmaceutical industry, used to improve the properties of powder formulations for tablet manufacturing. This comprehensive guide will take you through the wet granulation process, its advantages, challenges, applications, and recent innovations. Whether you are a seasoned professional or new to the field, this blog will provide valuable insights into the intricacies of wet granulation.

What is Wet Granulation?

Basic Concept

Wet granulation involves the addition of a liquid binder to agglomerate powder particles. This process enhances the flow properties and compressibility of powders, making them suitable for tablet formation. Unlike dry granulation, which relies on mechanical compression, wet granulation utilizes liquid to bind particles together.

Historical Background

The concept of granulation dates back to ancient times, but the wet granulation process as we know it today has evolved significantly with advancements in pharmaceutical technology.

- Binder Solution: A liquid solution used to facilitate the adhesion of powder particles.

- High Shear Mixers: Equipment that uses intense mechanical agitation to mix powders and binders.

- Fluid Bed Dryer: Machines that suspend powder particles in a fluidized state, allowing for uniform drying.

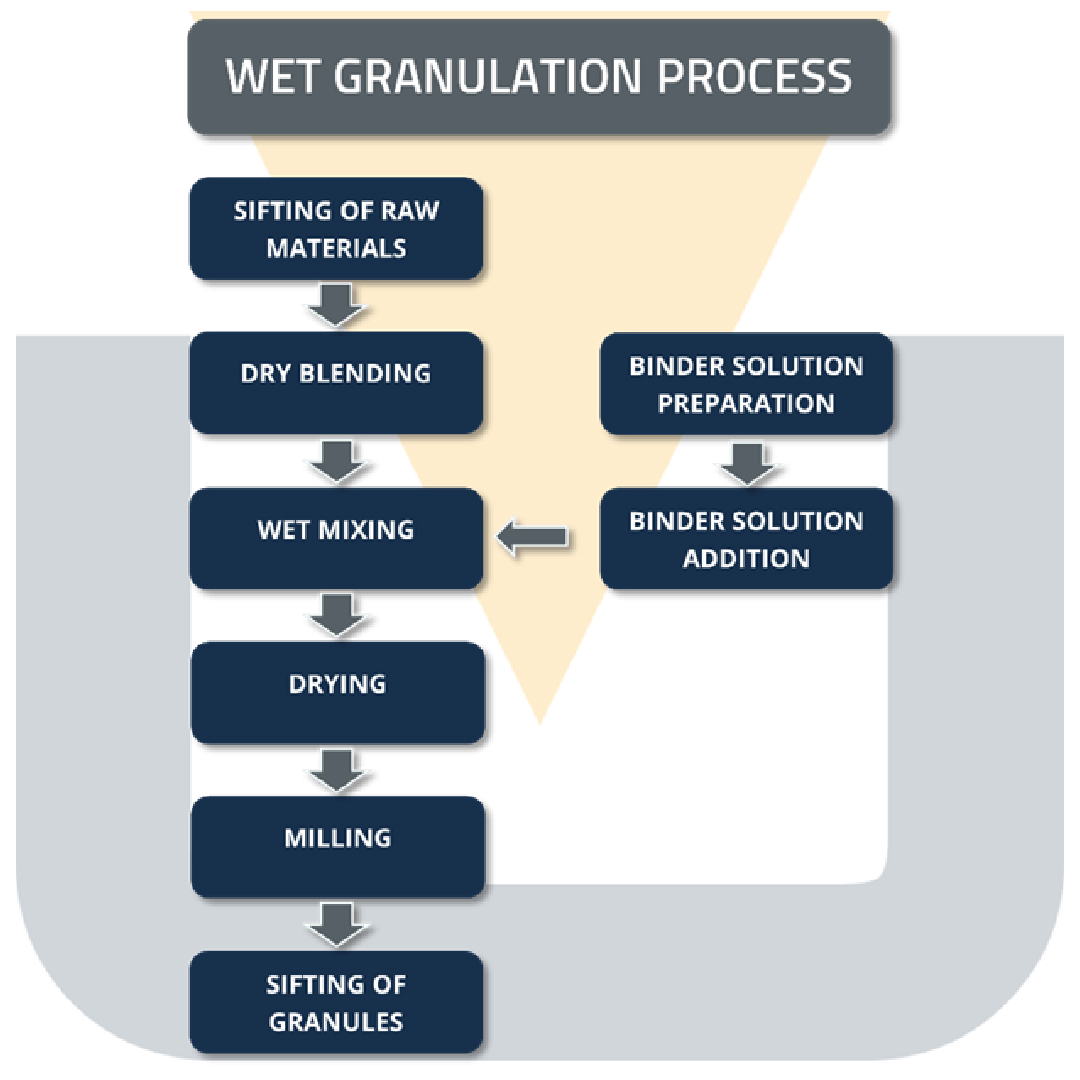

The Wet Granulation Process

Step-by-Step Explanation

- Sifting of Ingredients All ingredients, including the active pharmaceutical ingredient (API) and excipients, are sifted to remove any foreign particles and ensure uniform particle size.

- Blending of Dry Ingredients The sifted dry powders are blended to ensure uniform distribution.

- Preparation of Binder Solution binder solution is prepared by dissolving a binder in a suitable solvent. Common binders include polyvinylpyrrolidone (PVP), hydroxypropyl methylcellulose (HPMC), and starch.

- Addition of Binder Solution The binder solution is gradually added to the dry powder blend while mixing. This step requires precise control to avoid overwetting.

- Wet Massing The mixture is continuously mixed until a wet mass is formed. The consistency of the wet mass is crucial for the subsequent steps.

- Screening the Wet Mass The wet mass is passed through a sieve to break down large lumps and create uniformly sized granules.

- Drying The wet granules are dried using equipment such as a fluid bed dryer or tray dryer to remove excess moisture.

- Milling The dried granules are milled to achieve uniform granule size. This step is essential for ensuring consistent tablet formation.

- Screening the Dry Granules The milled granules are screened again to ensure uniform size and to remove any oversized particles.

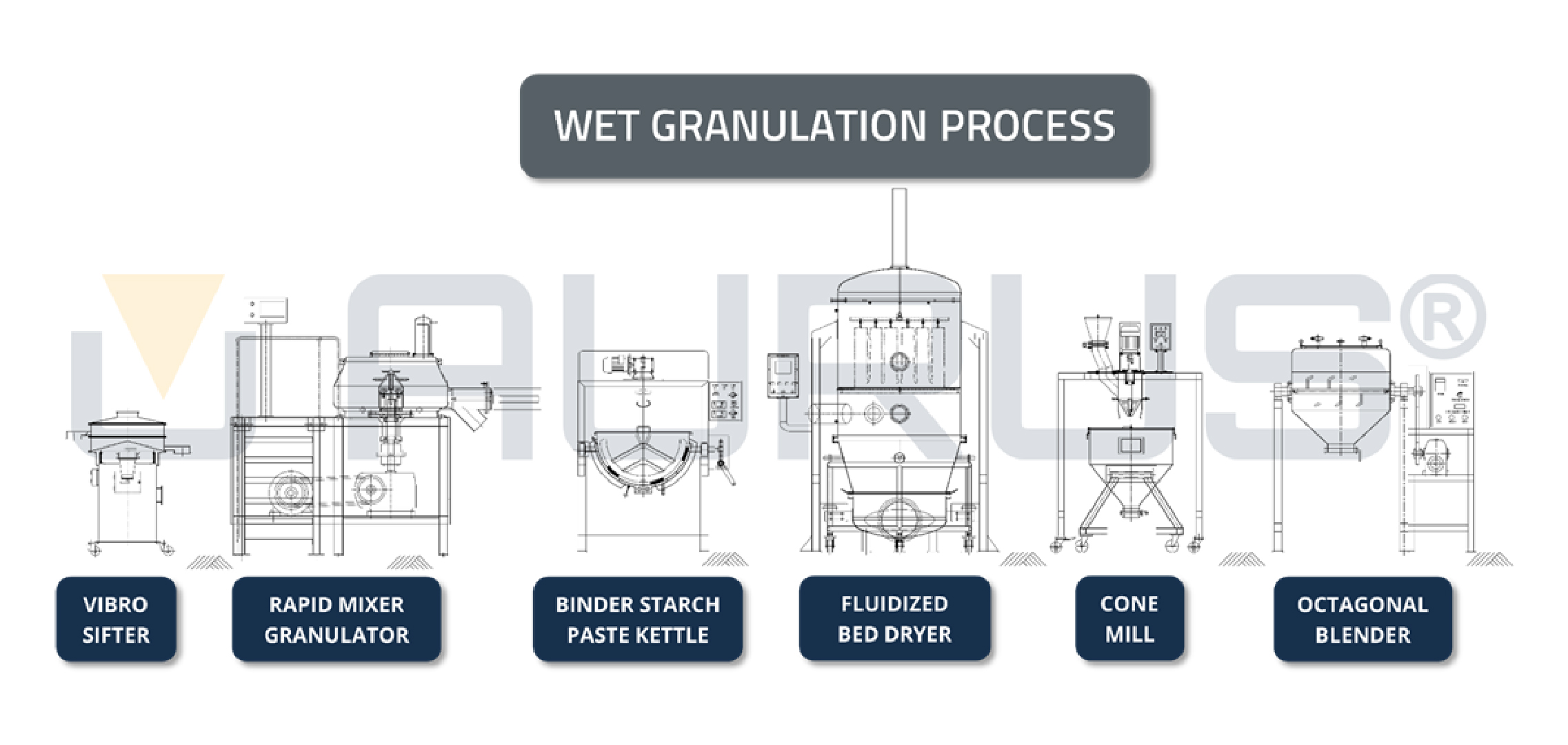

Equipment Used in Wet Granulation

- Equipment for Sifting of Ingredients Vibro sifters and other sieving equipment are used to remove foreign particles from the ingredients.

- Equipment for Preparation of Binder Solution Devices such as mixers and stirrers are used to prepare the binder solution. Paste Kettles are used to prepare thick binders such as starch.

- Equipment for Blending of Dry Ingredients Blenders like Octagonal Blenders, Conta Bin Blenders, Double Cone Blenders, V-blenders and ribbon blenders are used for uniform mixing of dry powders.

- High Shear Mixers High shear mixer granulators (HSMG), also known as Rapid Mixer Granulators (RMG), are commonly used for their efficiency in mixing and granulating powders.

- Fluid Bed Dryer Fluid bed dryer (FBD) offer uniform binder distribution and efficient drying, making them popular in large-scale manufacturing.Similarly Tray dryer or Vacuum Tray dryers are also used for drying.

- Equipment for Milling Mills like MultiMill, Comminuting Mill, and Cone mills are used to achieve uniform granule size after drying.

- Others Other equipment includes Planetary Mixers, Oscillating Granulators, and Rotary Mills.

|

Advantages of Wet Granulation |

Disadvantages and Challenges |

|

|

|

|

|

|

Applications in the Pharmaceutical Industry

Commonly Granulated Drugs Wet granulation is widely used for drugs that require precise dosing and uniformity, such as antibiotics, vitamins, and controlled-release formulations.

Case Studies

Case Study 1: Granulation of Paracetamol Paracetamol, a widely used analgesic, benefits from wet granulation due to its poor flow properties. The process ensures uniform distribution and compressibility, resulting in high-quality tablets.

Case Study 2: Controlled-Release FormulationsWet granulation is essential for controlled-release formulations, where precise control over drug release is required. The process allows for the incorporation of release-modifying excipients.

Advancements and Innovations in Wet Granulation

Recent Technological Developments Recent advancements include the use of process analytical technology (PAT) for real-time monitoring and control of the granulation process.

Future TrendsFuture Trends Future trends in wet granulation focus on continuous manufacturing, where the process is streamlined to enhance efficiency and reduce production time.

Conclusion

In summary, wet granulation is a versatile and widely used process in pharmaceutical manufacturing. Its ability to improve powder properties and ensure uniform drug distribution makes it indispensable for tablet production. Despite its challenges, continuous advancements and innovations are making wet granulation more efficient and cost-effective.