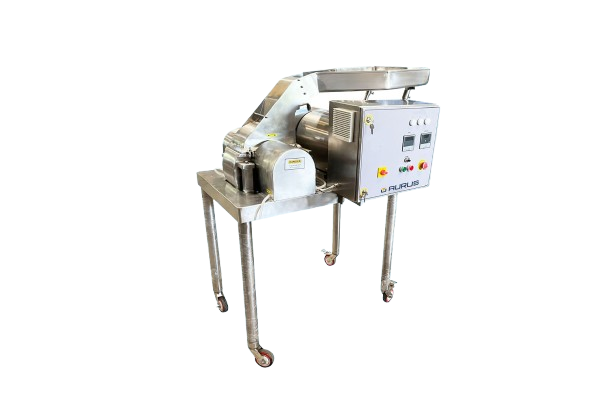

Primary Features

-

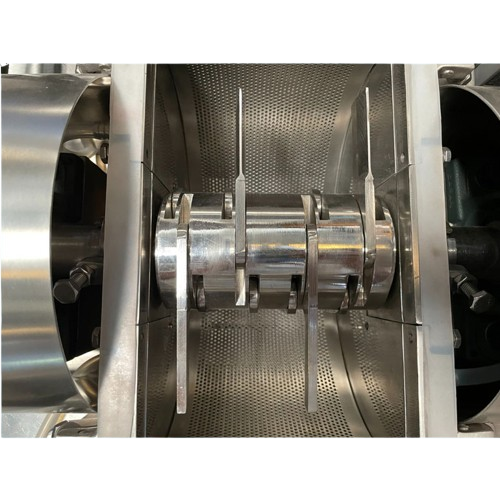

Precise control via an adjustable gap between rotor and stator

-

3-way valve with re-circulating pipe for maximum processing efficiency

-

Effortless output via separate discharge spout for highly viscous products

-

Ultimate value on investment with multiple variant options

-

On/Off switch via DOL starter

-

Easy to dismantle and clean